Have you ever held a product and thought, “This feels just right”?

That seamless edge, that perfect fit, the way it looks like it was made just for you — that’s not luck. It’s the result of precise design, smart engineering, and one manufacturing process that still dominates modern production: custom plastic injection molding.

I’ve worked with enough engineers and product managers to know one thing — you can design the best product on paper, but if your manufacturing process doesn’t support flexibility and speed, it can fall apart fast. That’s where this technology quietly changes the game.

Manufacturing Has Changed — and You Have to Change With It

You’ve probably noticed it too.

Markets don’t reward “mass production” anymore; they reward speed and adaptability. Customers want products that feel personal, brands need faster launches, and global supply chains no longer guarantee stability.

Traditional manufacturing can’t always keep up. You don’t want to wait six months for tooling, or waste thousands adjusting a mold after you’ve already started production. Modern businesses need processes that can pivot — and custom plastic injection molding fits right into that shift.

It’s not just about producing plastic parts anymore; it’s about producing ideas at scale — from prototypes to full runs, while keeping design intent intact.

What Makes Custom Plastic Injection Molding So Valuable

Let’s strip away the buzzwords for a second.

At its core, this process injects molten plastic into a mold cavity, cools it, and ejects a finished part. That’s it. Simple, right? But when you start tailoring that process — adjusting materials, mold geometry, and cycle time to your product’s needs — that’s when “custom” makes all the difference.

Here’s what happens when you go custom:

- You get tight tolerances even for complex geometries.

- You reduce assembly steps, because components are already integrated.

- You scale from 50 to 50,000 units without changing your base setup.

- You can test new materials (from standard ABS to bio-based polymers) faster than traditional machining ever could.

What I find most fascinating is how custom injection molding bridges two worlds: design creativity and industrial repeatability. You can tweak surface finishes, color mixes, or insert metal parts — and still keep consistent mechanical strength.

That’s the kind of flexibility that lets small brands compete with global ones.

Why Early Tool Design Is Your Real Competitive Edge

Now, here’s a mistake I see far too often: teams treat tooling like an afterthought.

They finalize the design, send it to manufacturing, and only then start thinking about mold layout. By that point, every millimeter you change costs time, money, and nerves.

If you’re serious about optimizing cost and quality, you need to involve injection moulding tool design early — at the prototype or pre-production stage.

Think about it this way: the mold isn’t just a tool; it’s the blueprint of your business efficiency. A well-engineered mold means:

- Fewer defects like warping or flash

- Faster cycle times

- Easier part ejection and maintenance

- Longer mold lifespan

Modern mold designers use digital simulation to predict flow lines, cooling balance, and gate placement before a single piece of steel is cut. That means fewer surprises and shorter lead times — both of which make your CFO very happy.

I’ve seen projects where early collaboration between product designers and tooling engineers cut production time by 30%. That’s not hype — that’s smart planning.

Differentiation: The Real Business Value Behind Custom Molding

Let’s talk strategy for a moment.

When every company claims “high quality,” what really sets your product apart? Design. Finish. Feel. That’s where custom plastic injection molding gives you control that others can’t match.

Take consumer electronics, for example. A unique surface texture can make a handheld device feel premium without adding extra parts. In automotive interiors, custom tooling allows brand-specific panel contours that reflect brand identity. Even in medical devices, where functionality rules, the ability to tailor form and ergonomics gives you an advantage.

Here’s what’s changing: customization isn’t a luxury anymore — it’s a requirement for brand recognition.

When you can adapt color, geometry, and assembly compatibility directly through your mold design, you stop competing on price and start competing on experience.

Sustainability Isn’t Just a Buzzword — It’s Smart Business

You’ve probably heard enough green talk to last a lifetime, but here’s the truth — sustainability isn’t just good PR; it’s operational efficiency.

In injection molding, waste reduction is measurable. By optimizing gate placement, wall thickness, and cooling time, you can use up to 20–30% less raw material per cycle. Combine that with recycled or bio-based plastics, and suddenly you’re cutting costs while meeting ESG targets.

Here’s where injection moulding tool design plays a huge role again.

A smart tool layout reduces energy consumption per part because it cycles faster and cools evenly. You also spend less on mold rework, which keeps machines running instead of sitting idle.

Some companies now integrate closed-loop systems that regrind sprues and runners directly into the next batch. That’s circular economy in real life, not just on a PowerPoint slide.

Collaboration: The Secret Ingredient No One Talks About

If there’s one lesson every manufacturer learns (usually the hard way), it’s this: design and production can’t live in separate worlds.

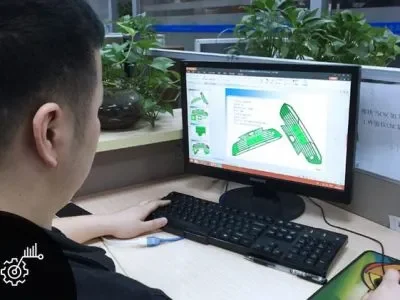

When your designers work in CAD and your toolmakers live in CAM, someone has to connect the dots. That’s where collaboration becomes a superpower.

We’ve seen teams save weeks by doing live design reviews — running digital flow simulations together, making micro-adjustments before cutting steel.

Today’s custom plastic injection molding projects often involve remote teams — designers in one country, toolmakers in another, and clients halfway across the world. Cloud-based design systems make that possible. You can share design files, add annotations, simulate the molding process, and sign off — all before the first mold trial.

This kind of agility doesn’t just reduce risk; it creates trust between engineering and business. When you and your supplier speak the same design language, quality naturally follows.

From Efficiency to Innovation: Where You Go Next

Let’s be honest — manufacturing isn’t easy. You deal with tight deadlines, moving specs, and that constant pressure to reduce costs without compromising quality. But that’s exactly why the combination of smart tool design and custom molding matters.

When you embrace these methods, you’re not just improving production. You’re creating a foundation for innovation — where your next product doesn’t take months to plan, but weeks.

You’ll start to see patterns:

- How a small tweak in draft angle saves hours in polishing

- How simulation data prevents short shots before they ever happen

- How better collaboration builds stronger supplier relationships

And suddenly, what used to feel like a stressful process turns into a predictable system that scales with your growth.

That’s the real promise of modern manufacturing — efficiency that unlocks creativity.

Final Thoughts: Building Better, Smarter, and Faster

If you take one thing away from this article, let it be this:

Good products aren’t just designed; they’re engineered to be manufacturable.

Whether you’re developing a consumer gadget, a medical component, or a complex automotive part, the earlier you integrate injection moulding tool design and custom plastic injection molding into your development process, the stronger your business foundation becomes.

We’ve seen companies double their output without doubling cost, simply by rethinking how design and manufacturing talk to each other. That’s not futuristic — that’s what’s already happening across factories worldwide.

So next time you hold that perfectly molded product and think, “This feels just right,” — remember, that’s not luck. That’s design, collaboration, and precision coming together in plastic form. And it might just be your next competitive advantage.